How Boldt gave a healthcare client a successful roadmap for future clinics

- Challenge: Build Owner’s first prefab + modular healthcare clinic and deliver exceptional value

- Solution: Use Join from napkin sketch to closeout to unify the team and create a proven template for the Owner’s future clinics

- Impact: Transparent real-time communication, a simpler TVD budgeting process, a happy client and new health clinic template

Challenge: Build Owner’s first prefab + modular healthcare clinic and deliver exceptional value

The people who build our hospitals and clinics are among the most sophisticated clients in the AEC industry. They want beautiful, modern, patient-centric structures for the people who work and heal in them. They also want the process of designing and building them to be as innovative, transparent, efficient, and predictable as possible. It’s for these two reasons–great buildings and a great building process–that one of the biggest healthcare providers in California entrusted The Boldt Company with not only building a new ground-up, OSHPD III medical clinic, but also with creating a modular + prefab playbook for all the provider’s future clinics.

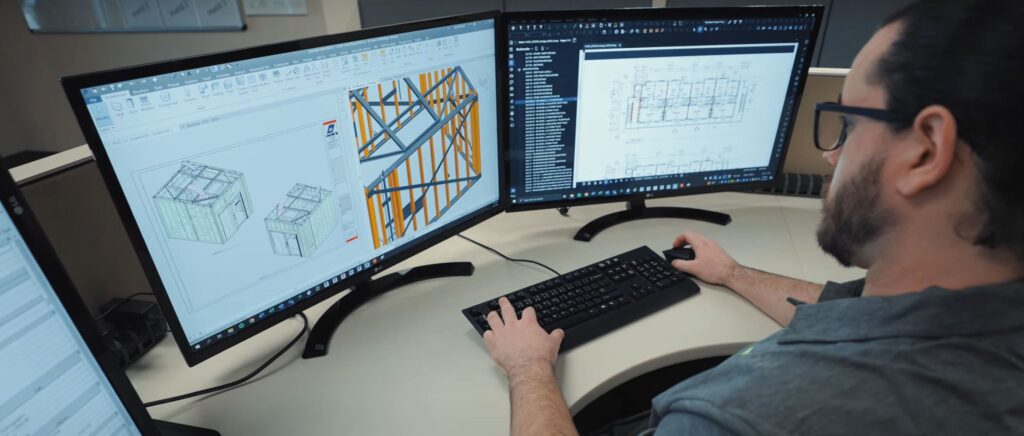

It was a challenge that was custom-made for Boldt’s Estimating and Preconstruction Manager Patrick Whaley. Whaley had recent and relevant experience meeting this particular Owner’s high expectations. In fact, he was part of a recent study commissioned by the client to standardize and productize healthcare construction with the objective of increasing speed to market and quality. The study, conducted by Boldt, Boulder Associates (architect), Mazzetti (MEP design engineer), and Mark III Construction (modular component designer/manufacturer), compared modular “pod” components with prefabricated “kit of parts” components for both a restroom and an exam room. The case study was so successful that the Owner hired this same team to build its most modularized and prefab health clinic to date: a care complex that would become the pilot project for all the Owner’s clinics going forward.

“On the first day, we generated 100 items (or ideas) to go back and price. It was a lot to really start to process in one day, but it got everybody pulling in the right direction, from Day One, on how to drive value.”

Estimating & Preconstruction Manager, The Boldt Company

Solution: Use Join from napkin sketch to closeout to unify the team and create a proven template for the Owner’s future clinics

With 11 Join projects under his belt, Whaley knew that getting this project team on the same page meant getting them into Join.

Atmosphere of trust among stakeholders

“The day after we got the call to move ahead with the project, the entire team met in the Big Room,” says Whaley. I said, ‘Today is our blue-sky day. Tell us anything and everything that you think will add value to this project.’ On the first day, we generated 100 items (or ideas) to go back and price. It was a lot to really start to process in one day, but it got everybody pulling in the right direction, from Day One, on how to create the best project for the target budget.”

As the architect on the project, Boulder Associates Architect III Jessica Edwardson, AIA, says that preconstruction can often be an adversarial exercise with the general contractor focused on cost and the architect focused on the design intent. “By putting the options in Join,” she says, “you begin to feel comfortable with the direction you’re taking because you can actually see all the options on the table and evaluate them objectively and dispassionately.”

Quick project setup and onboarding

Onboarding Join, Whaley says, was quick and efficient. After inputting the conceptual model into the system, his next step was to get all the stakeholders into Join.

Boulder Associates’ Edwardson, new to Join, says she was surprised at how easy it was to get up to speed on the software. “It’s a very simple interface and the team jumped in pretty easily with it, even folks that aren’t particularly tech savvy.”

New to both Boulder Associates and the healthcare industry, Edwardson says that because Join is so visual and transparent, using the Join platform helped her ease into the project “without it being too scary or technical.”

“It’s a very simple interface and the team jumped in pretty easily with it, even folks that aren’t particularly tech savvy.”

Architect III, Boulder Associates

Impact

Transparent, real-time communication

While Whaley knew from the get-go that Join would empower the team to make quick, informed, real-time decisions to reduce costs on the project, he first had to convince a particular group of the Owner’s project managers to use the platform. Apparently, it was an easy sell.

“This group of PMs really wants transparency,” Whaley says. “They want that accountability, and they want to be able to look at the project’s status on a weekly basis.” Join allows team members to discuss all the options, with attached back-up documentation, and to make informed decisions incredibly early in the process.

“By giving the Owner all their options as early as possible, they can decide when to take the savings or when to use those savings to make their patient experience–or even their staff experience–better. Join gives them that opportunity. It gives them early informed choices,” says Whaley. Join also provides a clear, 360-degree view of the project for the architect, design engineers, and other stakeholders, ensuring continual alignment with the Owner’s project goals.

“I like Join’s transparency, everything’s on the table. There’s no hidden agenda. Join makes me feel like I have a voice in the process, especially as a newer face to the field.”

Jessica Edwardson, AIA, Architect III, Boulder Associates

To make this point, Whaley references the decisions to replace the structure’s exterior metal-panel exterior with prefabricated composite panels, and to make necessary changes to some of the higher-end finishes that have become a trademark of the Owner’s clinics. “The sore points on this project were exterior panels and interior level of finish,” says Whaley. “They [the architect] gave up one (exterior metal panels), so I gave up one (interior finishes). That’s the whole purpose of this collaborative environment.”

As the architect on the project, Edwardson says she likes the visibility into all aspects of the project in Join, as it helps her to see the bigger picture, not just the items that have her name attached. “I like Join’s transparency,” she says. “Everything’s on the table. There’s no hidden agenda.” “Join makes me feel like I have a voice in the process,” she adds, “especially as a newer face to the field.”

Innovative cost-cutting solutions

When it comes to making tough decisions on a project, Whaley points out that “there’s more than one way to solve a problem.” Below are a few of the decisions the project team made in service of being responsible stewards of the budget while protecting the quality of the Owner’s patient experience.

EIFS Exterior Panels

The building’s exterior originally was going to be all metal panel, an extremely expensive finish. After much discussion and the architect reviewing multiple samples, the team decided to use a prefabricated exterior wall system called EIFS (exterior insulation and finish system). EIFS is a type of non-load bearing building cladding that provides exterior walls with an insulated, water-resistant, finished surface in an integrated composite material system. This change saved the team $300,000 – $400,000 on the project. The finished project will still resemble one of the Owner’s health clinics when patients drive up and will also fit in with the adjacent architectural context.

Controls

Another substantial savings on the project was what Whaley calls a “control swap out.” “We looked at another manufacturer that deviated from the Owner’s typical standard, which saved us close to $500,000.”

Glazing Reduction

“The team analyzed how to cut costs by reducing glazing,” says Edwardson. “We did a good job creating options and providing diagrams within Join so we could provide the Owner with the different percentages of reduction, the associated cost savings, and the imagery, all in one place. This allowed them to make a more informed decision.

Plantings

A particularly tough decision, says Whaley, was landscaping. “We asked ourselves, ‘what’s the savings if we go from several big-box trees to one 15-gallon tree? As it turns out, that’s $140,000, because we don’t have to account for unloading these massive trees with cranes. We can do it all with bobcats and forklifts.”

Maximized Modular + Prefab Components

“We’ve been relying on Mark III to find the highest efficiency of modular + prefab components,” says Edwardson. “We’ve also been meeting with the users to further work out that standardization. As of now, every wall within the building will be a panelized system that will be fabricated off site and then installed in the field. We are aiming for more than 50 percent of the exam rooms to be pods. We are also pushing for a lot of the restrooms to be standardized pods because of the efficiency of having them pre-plumbed.”

Buyout Savings

The team will save nearly $500,000 in buyout savings, says Whaley, “and we’re willing to put that in the log and say, ‘yes, we know we’re going to find that money through this process.”

A simpler TVD budgeting process

Join is especially useful in Target Value Design (TVD)projects, where different components of the project have their own team and budget. This medical clinic project is set up to track individual TVD budgets so that everyone can see how individual TVD budgets are trending.

“The way we used to do it, we would just put it all into a massive Excel spreadsheet,” says Whaley. “With Join, TVD budgets are easier to track.”

How would TVD have worked for Boulder without Join? “It would have definitely been less live,” says Edwardson. “We would have probably made a list of items and then tried to give each person instructions to go back to the drawing board, send them away, and then hope they’dcome back with the right information, which would then cycle back into budgeting. It would have been a lot more disparate, and definitely less collaborative, definitely less accountable, and reliant on individual stakeholders’ timelines instead of having this continuous adjustment and adaptability throughout the process.”

Whaley says the Owner appreciates how Join very simply communicates complex TVD project information. “In Join, all the costs are broken out.”

Heading into construction, budget on-track

With the 100% SD budget now complete and the project’s target budget met, the team is still exploring other cost-saving options. “Join helped us significantly reduce the budget on the project,” Whaley says,” while still delivering an exceptional experience for our Owner’s patients.”

First Join precon-through-construction project

Whaley says: “The Owner asked us: ‘When we get into construction, we’re still using Join, right? We don’t want to give this up.’ Our answer? Yes! We’re going all in on Join for this project. We are going to use it from preconstruction all the way through to completion.” (Construction will start in March ‘24 with a construction duration of 20 months.)

What does “all in on Join” look like?

“Our PM, Jacob Lashmett, has begun setting the project up in Join for construction,” says Whaley. “He’s currently working on getting the procurement items and the overall schedules and milestones into the timeline. To have Jacob, who really understands our schedule and all the deliverables, start working on it and get it pushed into Join, I think it’s going to be really cool.”

With the 100% SD phase complete, the team will now begin assigning items and attaching dates to drive the construction decision process. “And the big thing we’re going to use it for?” Whaley asks: “What’s our last responsible moment to make some of these decisions, including long-lead items. Are we on track to release this when scheduled? And we’re going to use it in parallel with Vplanner so that they’re tracking it both ways. We can then evaluate our effectiveness in meeting those last responsible moments.”

Whaley: “When we made our first presentation to the Owner and showed them, we had saved considerable money–just from the construction side–they were like, ‘Wow. This team is really getting it done. And, even better, you have the backup to show us how you’re doing it.’ That was pretty powerful.”

This project also marks the beginning of an entirely new capital project delivery system for the Owner. “This project is going to become this Owner’s standard model for their medical office buildings,” says Whaley, “That’s part of the reason they want this huge project history: to show exactly how we added value to the project and the template. And they love it; in fact, they’re over the moon with it.”

“The Owner told us, ‘Wow. This team is really getting it done. And, even better, you have the backup to show us how you’re doing it.’ That was pretty powerful.”

Estimating & Preconstruction Manager