How Preconstruction Decisions Impact Project Outcomes

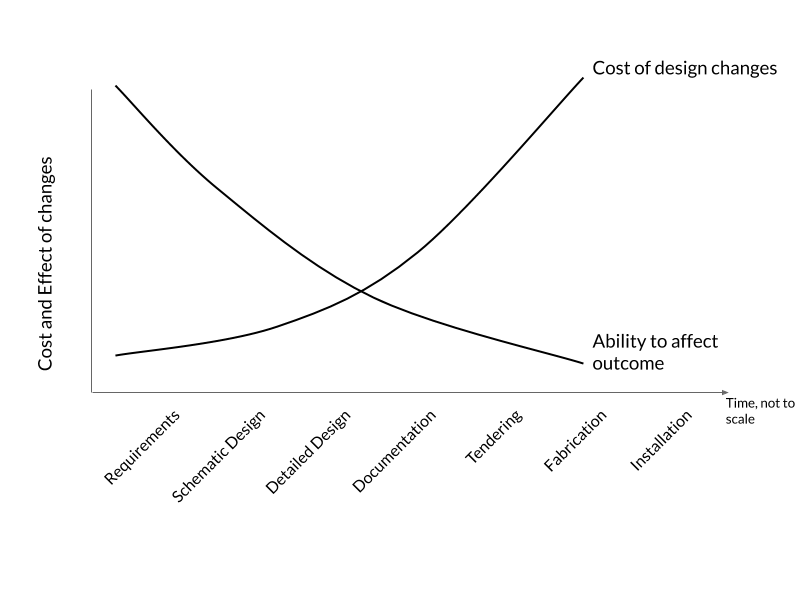

Making changes earlier in a project is cheaper and more impactful. This easily understood intuition was formalized by Patrick MacLeamy in a diagram describing curves of cost and effect varying over the course of a project. Appearing first in 2004, this diagram has been used many times to argue for early, more aggressive and integrated design approaches, typically taking the form of Integrated Project Delivery (IPD).

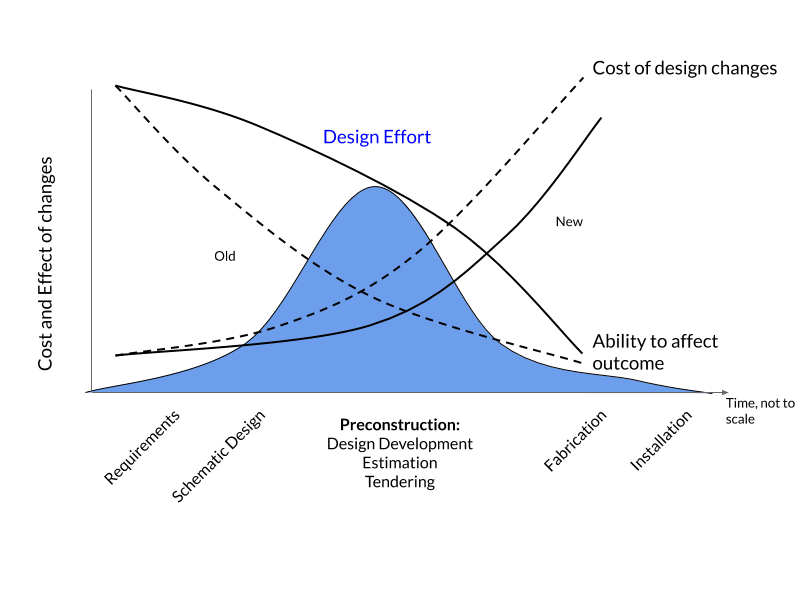

In this post we argue that instead of accepting the curves as they stand, we can and should bend them to bring increased impacts and reduced costs to decisions made during preconstruction.

Why Preconstruction Decisions are so Impactful

MacLeamy’s classic curve starts with the diagram below. This illustrates that as traditional design-bid-build projects progress through stages of design and construction, the cost associated with a design change increases while the ability of any given design change to affect project outcomes decreases.

These two trends compound late in a project when it is very expensive to make any design changes, and very difficult for these changes to meaningfully impact project outcomes. In an extreme example, when partition walls have been installed, it’s very expensive to reconfigure a floor’s program, and the building’s core layout is effectively untouchable.

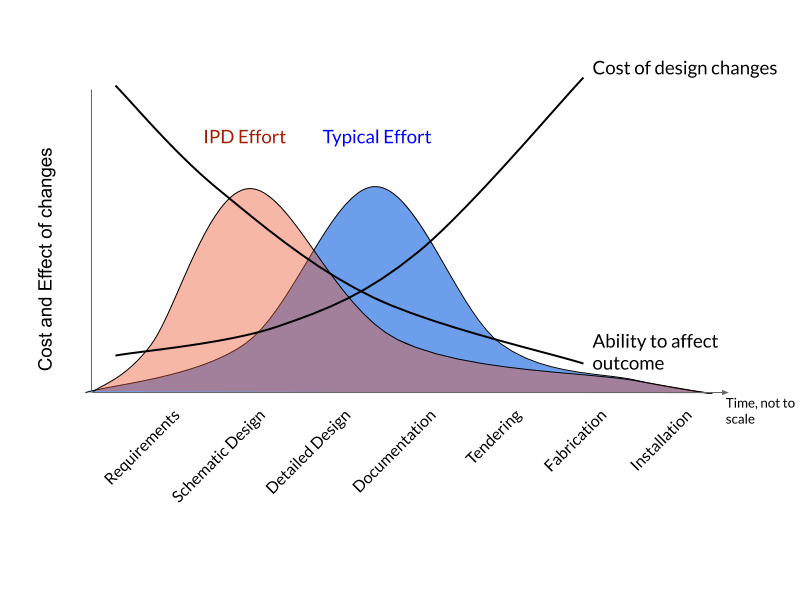

These curves are then overlaid with the level of design effort expended at each stage in traditional project delivery and in IPD project delivery. The argument goes: Traditional project delivery spends most of their design effort after it has already become difficult to change projects and impact cost, so why not do it earlier? IPD front-loads this effort.

The theory goes that doing this, more of the project would be worked out while still in a fluid state, leading to better, economical project outcome. While we hear good things about the collaborative environments that IPD encourages, there are some good reasons that this is not appropriate for all projects.

First, spending more on earlier stages of the project incurs additional financing costs for the substantial up-front effort. Costs of design effort are not trivial, and supporting those expenses may beyond the capital capabilities, especially in the world of developers who borrow to support construction.

Second, many changes in projects are not driven by the design team itself but do incur design effort. For example, a sudden shift in steel tariffs can lead to a reconsideration on the steel design, or new client requirements or scope changes emerge as the project progresses.

Third, it is often better to wait to complete many of the detailed design tasks — in an extreme example, detailing curtainwall connections on a skybridge in advance of finalizing massing is premature.

How Design-Build Helps

Fortunately, there is an alternative approach to consider: bend the curves. We see this happening with teams primarily on design-build and construction manager at risk projects, where owners and developers have bought in to the value of collaboration and teams are often acting in an IPD-ish manner.

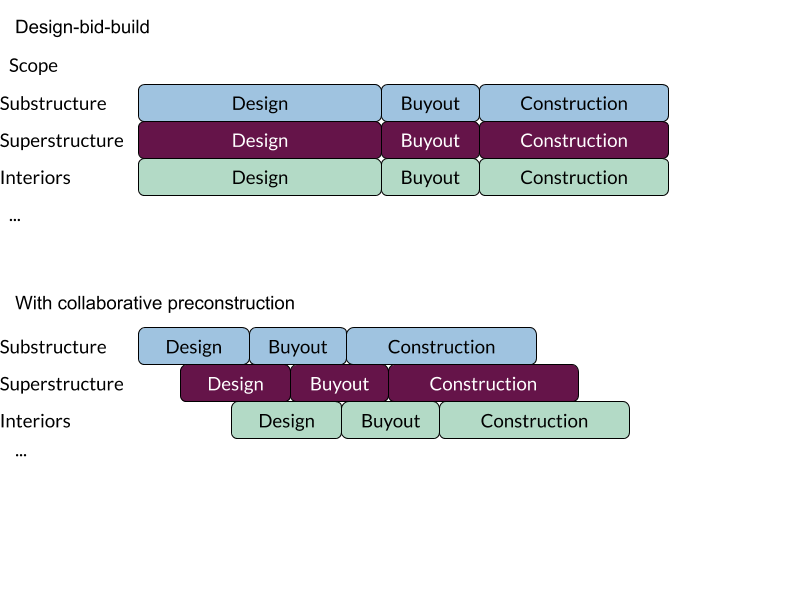

Teams engaging in these collaborative preconstruction phases have more opportunities to react in incremental ways without “boiling the ocean” with every change. This decreases cost because changes cast shallower ripples, and increases the potential to impact overall outcome through sequencing buyout and construction feedback.

Changes become more expensive as individual scopes pass through a fully fleshed out design, into purchasing, fabrication and installation. Each additional contract, level of development in design, purchasing agreement, and step in installation raises a barrier to change.

Some teams even use the number of people that would have to be informed of a change as an approximation of the change’s cost. If changes arising in one scope require updating dozens of other trade contractors and large numbers of substantially final documents, the costs will be high.

One large source of change in designs is feedback on the cost of a proposed design. With a collaborative preconstruction phase, key folks either from a general contractor or major trade contractors are involved and can provide that feedback before all other scopes have been finalized. This means that there are fewer barriers in place for changes that do happen, and the project preserves a low cost of changes for longer.

Similarly, the proressive engagement with trades common to collaborative preconstruction allows for changes to more easily have a wider impact. For example, teams that are engaging in progressive buyout may sign contracts for structural or facade scopes before interior finishes have been substantially detailed. This means that any deviation between estimated scope cost and where bids actually land can now be accounted for in future package’s details. If there’s extra budget, the systems can improve. If there was a miss, savings can be sought in the finishes.

Conclusion

In sum, these changes reduce the cost of design changes in projects, and increase the ability of preconstruction teams to impact project outcomes.

These project delivery methods are where the industry is headed — ask anyone whether they see themselves doing more or less negotiated or design-build work in the future, or look to any number of industry studies.

This transition is not without challenges. In an industry long schooled in managing complete document sets and proceeding down the waterfall of design, bid and build, teams must now manage design, estimates and budgets as moving targets through multiple iterations.

Preconstruction teams are being challenged to “price the white” on earlier and more preliminary drawings sets, where they have to make assumptions about project scope note yet reflected in incomplete drawings. Specifications are arriving after scopes have been bid. Cost certainty varies over the course of the project.

In many cases software tools have not caught up with these new modes of working, remaining rooted in traditional project delivery even as it has declined as a fraction of the market. At Join, we are excited to deliver tools that support teams embracing more iterations and delivering projects that owners love.

In the emerging world of preconstruction, this means providing workflow tools that support collaboration and effective communication and a data platform that leverages past experience and expanded supplier knowledge.