Layton innovates project delivery process to provide exceptional outcomes for new client

Challenge: Meet an aggressive hospital budget while improving the patient experience

Solution: Maximize TVD methodologies to balance budget and achieve project outcomes

Impact: Achieved target budget and increased value

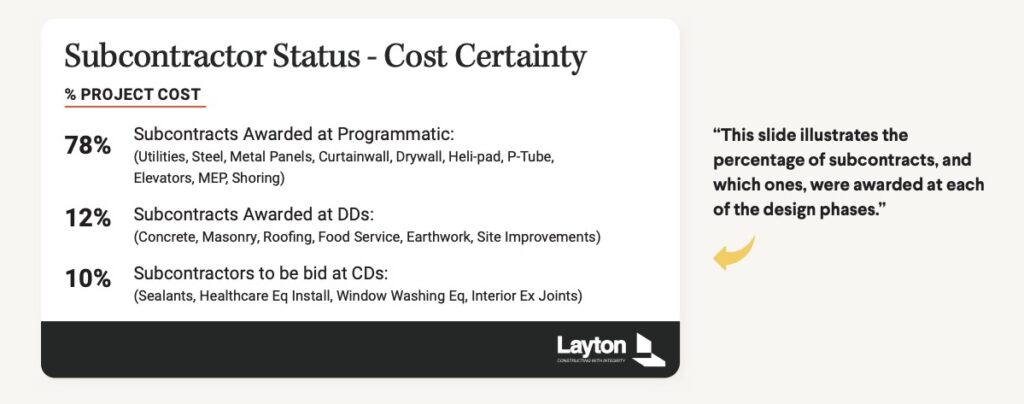

“We brought on 78% of the trades at the Conceptual phase, and we had 90% of the job under contract at the end of DDs. With this high level of cost certainty, the Owner got early project funding.”

Director of IPD and Design Build, Layton Construction Company

Challenge: Meet an aggressive hospital budget while improving the patient experience

A hospital in Montana had served its community well for 100+ years, but healthcare facilities (and healthcare itself) had changed radically in that time. It was time to build a new state-of-the-art facility to better meet the needs of the growing community, now and for the next 50+ years. In addition to providing the community with a new state-of-the-art facility, the Owner was committed to delivering the project following the tenets of Integrated Project Delivery (IPD) and Target Value Design (TVD) methodologies. Layton Construction and HDR quickly mobilized with a clear, two-part mission:

1. Create a revolutionary and patient-centric hospital design

2. Meet an aggressive budget

While the Owner’s most recent hospital project was “very much schedule driven, cost is the main priority on this project,” says Sr. Estimator Brandon Babin. Tasked with reducing costs, the Layton team would need to “evaluate everything to arrive at the best possible cost solution,” Babin explains. But such a rigorous effort could quickly get the project off track, so Layton decided to hyper-streamline the process for evaluating, making, and tracking decisions. To that end, the team deployed Join– proven preconstruction software.

Layton Construction Company

Since 1953, Layton Construction has been perfecting our craft, growing nationwide, and improving the built world by providing predictability in an industry that’s anything but predictable. We also joined the STO Building Group in 2019—expanding our reach, resources, and portfolio. Throughout it all, we’ve constructed with integrity.

No matter where you are or who you’re working with, you get the same Layton every time.

Solution: Maximize TVD methodologies to balance budget and achieve project outcomes

Create a high-performing team built around a clear vision

With the decision made to use Join preconstruction software, the Layton team quickly onboarded and trained the existing project team on the collaborative, cloud-based platform. They opened up the platform to anyone who showed an interest, and adoption happened quickly thereafter; within three months the entire team was onboarded (69 users from 11 different companies in the platform). This included Layton, HDR, the Owner, and multiple trades. “When someone expressed an interest, Brandon and I would show them how to use Join in the Big Room,” says Director of IPD and Design Build Michael Blasingim, “and it was like literally five minutes worth of training. It’s so quick and easy to use.”

“Our mission was to maximize the project budget without negatively impacting – or, better yet, improving – the patient experience.”

Senior Estimator, Layton

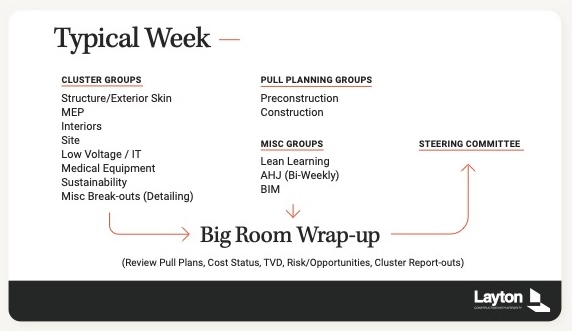

“While not contractually an IPD project, our process is very similar,” says Babin. “We are employing IPD principles on the project, including operating with the architect and the TVD Cluster Groups in a Big Room environment to optimize project outcomes.”

To ensure the collaborative team was 100% clear on the project vision and how to get there, Layton leadership and the Owner “really took the time to make sure everyone was on the same page,” Babin adds. “We had 7 guiding principles: 1) patient experience, 2) end-user input, 3) flexibility, 4) fiscal responsibility, 5) efficiency, 6) safety and security, and 7) sustainability. Our mission was to maximize the project budget without negatively impacting – or, better yet, improving – the patient experience.If something reduced cost but potentially compromised another guiding principle, it had to go all the way up the chain for others to weigh in on the decision.”

“It was like literally five minutes worth of training. Join is so quick and easy to use.”

Director of IPD and Design Build, Layton Construction Company

For collaborative teams to thrive under the IPD/TVD model, they need an environment where each member is empowered to bring their best thinking and solutions to the project. This was the culture that existed on this complex hospital project. Ideas were bubbled up from the weekly TVD Cluster Groups to the weekly Big Room meeting, where they were documented and either rejected or accepted. On the rare occasion when an idea was in conflict with one of the 7 guiding principles, or wasn’t included in the original scope, it would be elevated to the Steering Committee, composed of Owner, GC, and architect executives.

“In a collaborative culture like this, you can’t have anyone working in a silo.” – Michael Blasingim,

Director of IPD and

Design Build

According to Blasingim, 98% of the decisions were made by the Cluster Groups with only a small portion having to go up the chain for approval. This allowed for true empowerment by the team members. While Owner costs (medical equipment, sustainability, detailing) were not part of the team’s contract, they still followed the same guiding principles and meeting structure. “In a collaborative culture like this, you can’t have anyone working in a silo,” says Blasingim.

“If you don’t have the whole team bought into the philosophy, it won’t work,” Babin adds. “It will just fall apart. The Owner did a great job of keeping that philosophy front and center, and the team did a great job of embracing it.”

“This really is a high-functioning team,” Blasingim says. To get the team to that level of performance, and to help keep them there, the Layton team maintains an IPD training deck for onboarding new people to the project. A similar slide deck is used to report project status to the team and the Owner.

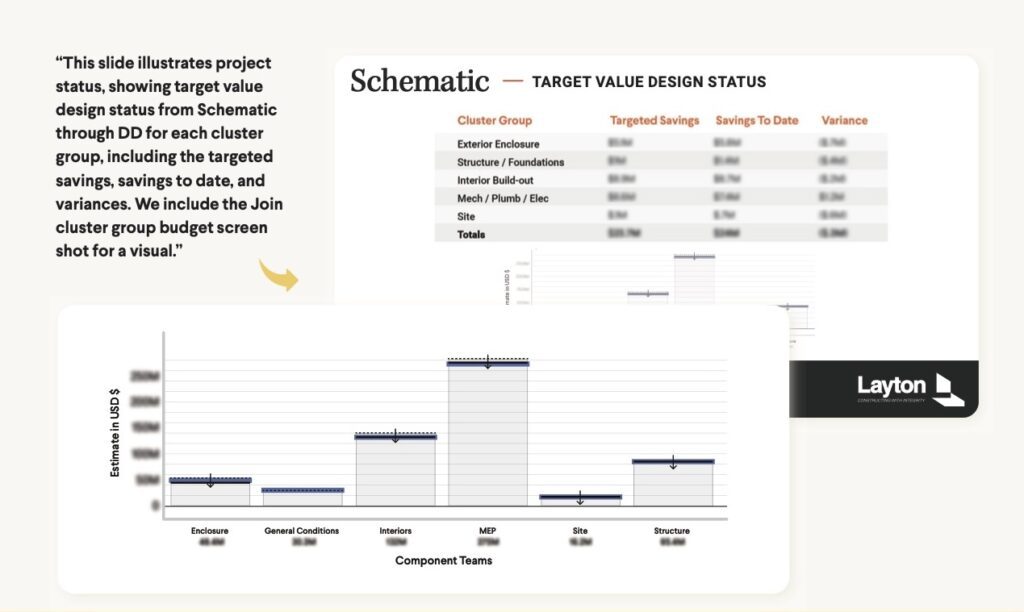

Below are slides from the deck with a brief description from Blasingim:

Blasingim adds that having a place to visibly track cost-saving options has also sparked competition among the different Cluster Groups. “From the beginning, everybody was bringing up ideas. The subs were bringing up ideas, the architect was bringing up ideas, we were bringing up ideas. In fact, it became pretty competitive. If a Structure team member brought up an idea that was accepted by the Interiors group, the Structure team got the credit. But the team as a whole celebrated successes together. After each big win, we would all go to the local beer garden down the road.”

Onboard trades at Conceptual Design

Layton fully committed to a key tenet of Integrated Project Delivery: earlier builder participation. IPD benefits can only be fully realized when you bring together the designers and builders early enough to synergistically optimize the building. Some project teams who experiment with IPD only tip-toe into the shallow end of the pool and bring in their MEP subcontractors during mid-to-late Conceptual Design or, worse, in the Design Development phase. By contrast, Layton dove head-first into the deep end of the pool, onboarding over 78% of the trades (by cost volume) during the conceptual phase. This allowed early design assumptions to be quickly vetted with subcontractors, their vendors, and, in some cases, even the manufacturer. In doing so, Layton effectively integrated their entire supply chain to harness the vast knowledge and superior expertise of these individuals and lean into the project’s goals.

“We were showing the Board things like this deck; our trendlines, our target values, our early buyout. And it gave the Board a comfort level with our costs.”

While vertical supply chain integration is common in large manufacturing industries (e.g., automotive), it is unique to see it done in the commercial construction world.

Says Blasingim: “We brought all our major trades on at the Conceptual Design (Programmatic) phase. In fact, we had 78% on board, which provided a high level of cost certainty to the Owner. At the end of DDs, we had 90% of the job under contract, allowing us to go to GMP at the DD level, not the CD level. Because of this early cost certainty, the Board was able to get early project funding. We were showing the Board things like this deck; our trendlines, our target values, our early buyout. And it gave the Board a comfort level with our costs.”

“At Conceptual Design, we onboarded all the major trades–including mechanical, electrical, glass, drywall, elevator, pneumatic tube, steel–and they were participating in our meetings with us,” says Babin. “We had the curtainwall and the metal panel subcontractor and their manufacturer with us in the meetings, and one of the big things they ended up finding was a glazing and metal panel that could save $20 to $30 dollars per square foot. That one decision–switching to a different type of system that has the same look but is a lot more efficient–was incorporated during Schematic Design and helped us save 8 percent on the 10-story tower portion of the building.”

What does that one decision look like in Join?

Says Babin: “That one is Item number 87, the culmination of about six weeks of intense teamwork, where we looked at going from straight curtainwall, to looking at a ribbon-window set-up, to doing punched openings. We had 7 or 8 options. And that’s what’s great about TVD and a Big Room environment. For someone in preconstruction, you can discuss what the designer really wants early on; what materials they are wanting to use. You can just walk over and have a conversation with them.”

“That’s just a classic example of what this team was able to accomplish,” says Blasingim. “We had our exterior subs on board. And we had a two-hour meeting between the architects, the engineers, and our subs; and then we actually got the material suppliers on the call with us to understand where to break things out, how to attach them. And from all of us working together, all the way down to the manufacturer level, we were able to walk out of that meeting saving more than $5 million dollars. And we did this at the Schematic level.

Further, Babin adds, that detail is captured in Join. “Everything is tracked,” he says. “Five years from now if someone wants to know why we did something, they can find the answer in Join, including why a decision was approved and who approved it.”

Build trust among project stakeholders

Because of the intensive collaboration on the project, and the transparent and open decision-making process the team enjoyed, there was a heightened level of trust and communication among the project’s stakeholders–including the Layton team, the architect, the major trades, and the Owner.

The Owner, new to Join, is enthusiastic. “They love it” says Babin. “They really enjoyed being able to see the Join dashboard. They could easily see the big picture; how the space above the budget line represents risks; the space below the budget line represents opportunities. We accepted up to 40% of the opportunities.”

“Five years from now if someone wants to know why we did something, they can find the answer in Join, including why a decision was approved and who approved it.”

Blasingim elaborates on the importance of communicating percent of accepted items to both the team and the Owner: “It tells the project story. You can look in Join and see that the big picture looks good, that you’re trending in the right direction, but, ‘Hey, Interiors…you’re not going to meet your goal because to get $1 million worth of savings, you’re going to have to have about $2.5 million worth of options (or items) to get to 40%.’ So, when you have that conversation with Interiors, then they get to meet as a team and talk about how to come up with more cost-saving solutions.” Additionally, the Owner gets detailed insight into the roadmap of the team’s journey to the target budget.

The benefits of early trade partner onboarding

How did Layton ensure that the Owner was getting fair pricing in light of the very early onboarding of the major trades? “Many Owners would think if they award this early, it’s not going to be competitive,” says Blasingim. “But we still did a competitive RFP process; we sent out value-based RFPs with the appropriate architect or engineer involved, including certain levels of breakdown, unit rates, and mark-ups. And it was 100% open book.” Layton also stipulated in the RFP that the subcontractor was being awarded the preconstruction contract only; if performance did not meet expectations in the precon phase, Layton reserved the right to bid the job back out.

The trades, Blasingim admits, initially may have experienced some discomfort in exposing their whole budget. “But once they realized we weren’t using it to beat them over the head with it and instead were using it to understand how we could design to a cost, how we could establish our TVD buckets and hit them, they saw what we were trying to do. We were able to establish a foundation of trust. Now you have folks really shoulder to shoulder, talking about the actual challenges of production, how to really solve them and not worry about covering the fee.”

HDR, the architect, appreciated the efficiency of the IPD/TVD process, particularly the early trade involvement. Says Blasingim: “We were actually having the subs do the shop drawings, give them to the architect, and let the architect put those in the drawings. So the architect loved it because they didn’t have to try to figure out what these details look like, only to have the sub later say, ‘Hey, these details don’t work.’ We were going in with a fully coordinated set of drawings because we brought all these people in so early. Our BIM coordination was also being done at the same time, so that the final CD set will be fully coordinated on the MEP side, too.

“Again, we were 90% bought out at DD and going into CDs with the BIM process complete and with 100% fully coordinated drawings. We actually had some of the subcontractors provide a lot of the detailing for the architects, so instead of the architects providing exterior window details that may or may not ever work, we actually had already selected which product we were going to use and took those details from that particular system and put those into the drawings. The architect loved that they didn’t have to draw a bunch of stuff that didn’t make sense or wasn’t going to be used. It was a very lean process. What did that save? We didn’t have an alternate universe where we were comparing this process to the old school way, but we have some data on how much it cuts down on RFIs. You can also look at our Join log. It saved at least $36 million. It also takes risk off the project.”

Keeping the spirit of TVD going for the life of the project

Babin adds that even when the team neared its target budget, they never stopped looking for additional opportunities. “Each Cluster Group took their cost-savings to the very limit, without compromising safety, quality, and user experience,” he says.

Both the Owner and the team, Babin says, were “mission-driven” to continue to explore new ways to add value to the project. “It was our team culture. We were not just going to hit our number and hit the brakes; we kept going full throttle. Because stuff is going to come up (e.g., cost overruns, proactive contingencies in anticipation of cost overruns) and you’re going to need some cushion. That is how TVD works.”

Layton and team is on track to deliver the project in 2029. What can the community expect from the team’s collaborative efforts? The hospital is designed to optimize patient care and flow by putting departments that are now spread out closer together; every room will have a view of the city or the mountains; and increased oxygen capacity will allow each room to be transformed into an ICU very quickly.

“The team has shown the Owner, new to IPD/TVD, that the process actually reduces risk and provides greater predictability.”

Director of IPD and Design Build, Layton Construction Company

Impact: Achieved target budget and increased value

The Layton team met and exceeded its target budget, reducing the overall construction costs on the project by 8 percent.

Convinced key client about the benefits of IPD/TVD for future projects

The team has shown the Owner, new to IPD/TVD, that the process actually reduces risk and provides greater predictability. “[The Owner’s] leadership team was really put at ease when approving the GMP at the DD level,” says Blasingim. “They understood that 90% of the project cost was under contract and our drawings were fully coordinate, which gave them a predictable outcome.

Developed a successful–and repeatable–TVD onboarding playbook for STOBG teams

Layton is a part of STO Building Group (STOBG), a family of 14 construction companies that share construction resources like bonding, trade relationships, real-time data, and lessons learned. Company leadership, impressed with Layton’s use of TVD + Join on the Montana hospital project, has shared the team’s TVD onboarding playbook and best practices with other companies within the STOBG portfolio.

The use of TVD + Join has enabled has enabled the Layton project team to achieve remarkable results on the project. To demonstrate his own team’s hyper-effectiveness as a result of TVD + Join, Blasingim opens the Join platform on his computer and navigates to the project’s cost trendline. He points out the number of items the team has proposed, accepted, rejected, or has pending. “This just speaks for itself,” he says. “Look at that trendline; it doesn’t get any better than that. This Join tool has been great for us on our large projects; just being able to visualize compared to Excel. It’s just been invaluable.”

“Look at that trendline; it doesn’t get any better than that. This Join tool has been great for us on our large projects; just being able to visualize compared to Excel. It’s just been invaluable.”

Director of IPD and Design Build, Layton Construction Company