XL Construction leans into collaboration to help UCSF build its first mass timber project

- XL expands its mass timber portfolio and experience

- UCSF gets the mass timber project it wanted, at the price it wanted, as well as an outstanding owner experience in the process

- The building’s end users will enjoy a work environment that fosters both productivity and joy

“We thought this would be a perfect opportunity to show UCSF Health our mass timber skillset, while also providing a world-class workplace.”

Project Executive

Challenge: Program changes and unique schedule constraints challenged XL Construction’s plans for providing UCSF Health with its first mass timber project

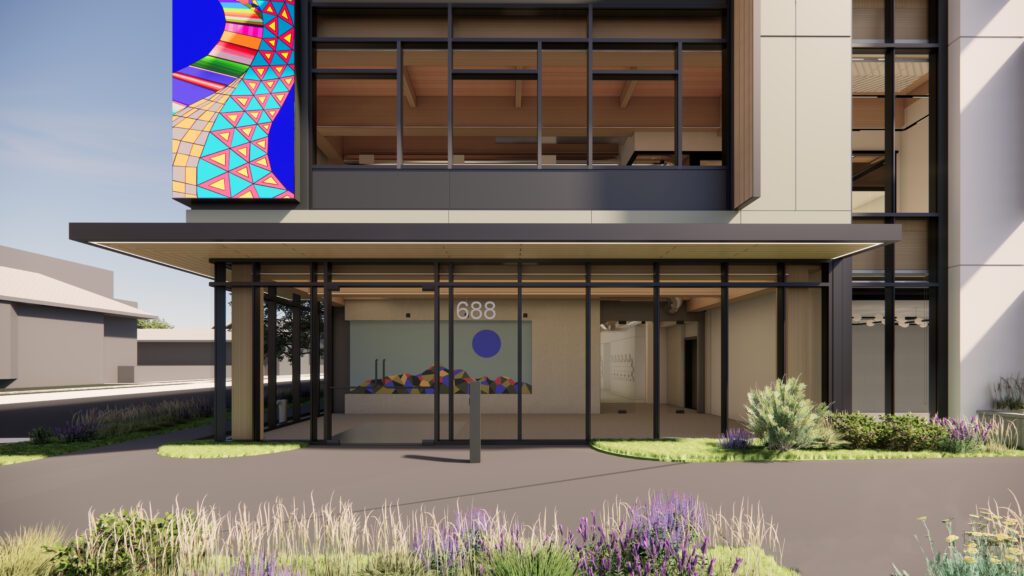

It is not unusual for a client, even a super-sophisticated client like UCSF Health, to not have a project’s entire scope and program developed when it issues the RFP. Such was the case with the UCSF Benioff Children’s Hospital Oakland new Administrative Support Building (ASB), a ground-up, 31,000-sq.-ft., three-story structure that is being delivered under a design-build partnership between XL Construction and RMW Architects.

The RFP issued by UCSF Health was evaluated under a “Best Value” selection process. Selection criteria prioritized: 1) design innovation and prefabrication, 2) time to market (schedule), 3) project team, 4) engagement of small and local businesses. While the RFP prioritized design innovation, there were design parameters such as building footprint and massing, as well as required design performance criteria. While some of these elements were defined, there remained a lot of intentional optionality going into the project.

Project Executive Terry Wong says the XL/RMW team understood the project site limits and square footage, but did not know how many people would occupy the building or what kind of services they would need beyond an open floorplan. “All we knew coming out of the interview,” she explains, “is that UCSF and the team should prioritize the schedule and explore multiple options for all the building systems.”

That information, however, sparked an idea. “We as XL Construction have a specialty in mass timber,” says Wong, “and we thought this would be a perfect opportunity to show UCSF Health our mass timber skillset, while also providing a world-class workplace for this first construction project in the BCH campus’s ambitious modernization program.”

XL Construction is a leading general contractor whose mission is to “build to improve lives.” XL partners with today’s leaders in life sciences, advanced technology, commercial, civic, healthcare and education sectors to create places that make its communities better. The company’s focus and passion for team success has earned it a network of great partners and a reputation for putting people first. XL Construction is consistently ranked among the top general contractors in Northern California. In 2020, the company was named ENR California’s 2020 Contractor of the Year and the #1 Best Place to Work in the Bay Area. www.xlconstruction.com

Solution: The XL team unlocked the power of team alignment and early collaboration to solidify big program and design decisions and move the project forward

Collaboration as early as the pursuit stage

The XL/RMW team believed mass timber would complement UCSF Health’s goals for both the new building and the $1.6 billion modernization of the 11-acre BCH Oakland campus, but they didn’t want to make that decision without first presenting all the options to the owner.

Instead, Wong says, “the team put together multiple A3s (even though we were just in the proposal stage) that had three different structural options for UCSF to pick from. We made our recommendation, but we showed our homework in a way that detailed not only the structural system, but also the exterior system, the MEP systems, right down to the kind of elevators. Our strategy was, ‘Hey, this option checks these boxes off your criteria, but not these.’ So, we started with a very collaborative attitude going into this. And I think UCSF Health really liked that.”

The strategy was successful. In fact, UCSF Health liked XL/RMW’s collaborative approach so much they awarded the design-build team the ASB project.

“The XL/RMW team really showed UCSF Health that they had both the solutions and the systems to help us achieve our ambitious goals on this project.”

UCSF Benioff Children’s Hospital Oakland, Sr. Project Manager, Design & Construction

Making the decision for mass timber

“Mass timber was not the least expensive option, and in the RFP we had variations and hybridizations from everything from precast to steel to quick-erect steel, to quick-erect steel with mass timber, to mass timber,” says Sr. Design Build Manager Corrie Messinger. “We also did a number of different systems, including HVAC and electrical. It was very much a value-based approach.”

XL/RMW’s expertise in mass timber was one of the contributing factors in UCSF Health electing them following the RFP. In early discussions with the team after they won the project, UCSF Health expressed interest in moving forward with the mass timber structure provided the budget could be aligned to allow for that option.

“Part of the story of this job,” Wong says, “is that we started with a higher budget than what the client had budgeted for, but they had entrusted us with the process to successfully drive the cost down. So, the team goes into Join and begins making decisions.”

Getting Clarity on the Program

The team first had to get a clearer understanding of how the building would be used, which required very early and collaborative decision-making.

It was clear from those early RFP discussions that the building would be used as a “make ready” structure for the campus. “There is a $1.6 billion hospital project that is right on the heels of this project,” adds Messinger. “And in order for that project to get underway, they have to demo several existing buildings and even part of the current hospital–essentially the entire southern half of the campus. What that means is that there will be a large number of staff that will need to be relocated to the ASB.”

Additionally, and of great impact to both the schedule and the budget, UCSF Health’s design criteria for the ASB continued to change. This included an exterior redesign, revisions to the number of final occupants, and switching from an open-office concept to one that included a mix of both open-office and closed-office spaces.

“We also knew we had a very complicated permitting process that was happening after this,” Messinger adds. “We’re dealing with four agencies on this small project. In order to hold to the schedule, we presented things as ‘decision-ready’ to the owner so they could quickly validate decisions and the team could move forward.”

The timing of how quickly the team could identify and vet options was critical to getting through the design cycle.

“That speaks volumes about the team,” Wong says, “But also about the tools we used, including Join.”

The RMW project team, which hadn’t used Join before, quickly began to understand how the platform could speed decisions. “At first, Terry and Corrie (XL) would put things in Join,” says RMW Principal Caitlin Pastori. “Then as we started moving through the job and there was so much ideating happening, the design team started inputting things into Join and uploading sketches. And for us that was helpful. I didn’t have to rely on Terry seeing my email, understanding it, and inputting it into Join. I was able to be proactive and put those things in there and tag her on them, so she was alerted. And then I could check on the status.”

Making Quick Decisions around Schedule and Cost

The team leveraged Join’s Scenarios feature throughout the project, but it was particularly useful for making informed, collaborative decisions around the following:

A shortened schedule

While working through precon, the team was informed that they needed to compress the schedule. Says Messinger: “UCSF Health had a mandate, and we were going very fast on this project, then they asked us to move up our GMP for funding purposes. We had to make some very quick decisions because it was already an aggressive assembly of the GMP. Terry ended up going through a number of scenarios with UCSF, and working through that approach, got us down to target.”

The rising cost of mass timber

While UCSF Health was all in on the project being a mass timber structure, Wong says, the team had to stay within the target budget, which was proving tough to do. While mass timber is typically more expensive than a steel or concrete structure, the cost of the material had continued to rise during the RFP process and into the design phase.

Interior program changes

Since it wasn’t 100% clear who would be using the building, the team met with McDonnell (vs. specific end users) to gain clarity on the building program. It was a very focused decision-making process,” says Messinger. “UCSF Health had a general sense of head count, but they did not want to tailor the building to a specific user; instead, they wanted to take a standardization approach and have flexibility.”

UCSF Health also initially wanted the office space to be open concept; however, it was later determined that the potential users, regardless of their title, would often need private space. This required multiple studies to arrive at the right percentage of open to closed office space.

“So it was really getting down to the number of offices and the percentage of open seating areas,” says Messigner. “And then from there it was really studies in how we could maximize head count, or how we could maximize an efficient number of huddle rooms as another exercise. Following that was a large exercise of evaluating flexibility for the campus to operate as an emergency operation center. And so we priced out those alternatives and identified some opportunities for cost savings in a way that the owner could digest and make a decision.” [See sidebar at right, which outlines the team’s decision-making workflow.]

The way the building came out, he adds, will serve stakeholders from physicians to administrative staff with a “very fluid overlap between them.”

Prefabrication

“One of the cost-saving Scenarios we evaluated,” says Messinger, “was to take out some of the built structure and go to prefabricated pods, which is something we brought in from our corporate experience but was a little bit new for UCSF Health. ” The team landed on the decision of using prefabricated pods for the two- to eight-person conference rooms in the building, called “focus rooms,” as well as in some other locations, Messenger says, which gives the owner the flexibility to remove them in the future if they want to increase head count in the building.

Exterior options

Another of the bigger decisions on the project involved the exterior system. The team evaluated cement plaster panel systems vs. a stucco EIFS system. “We were going through different percentages,” Messinger explains, “because the cement plaster panels have a higher level of finish, but also a higher cost.” After reviewing all the options, the team decided on a mix of EIFS, as well as fiber cement panels at the more visible corner, giving UCSF the look it desires.

“The Administrative Support Building is actually going to be right at the front door of the new hospital,” says Messinger. “UCSF Health cared a great deal about the presence of this structure, so we went through multiple scenarios about how we could incorporate the aesthetic of mass timber outside the building. Since real wood doesn’t actually hold up very well when it’s in an exterior condition, especially under the California sun, we evaluated multiple alternatives to wood-look systems to try to bring that language outside. We leveraged our trade partners to provide us with that data and worked closely with the design team.”

“The underside of the canopies were going to be actual wood,” Pastori adds. But in addition to not weathering well, there were also maintenance concerns, so the team began researching options. “We wanted something similar to the wood look we were going for so we engaged the trade partners and were able to choose those wood-look materials from the collective group.”

The workflow

“In terms of cost and redesign, the building was getting very expensive compared to the initial budget and what the original criteria allowed,” Wong says. “We used Join to push these complex design decisions.” What did that look like?

Wong and her team got all the trusted partners in the room and started putting ideas on the page.

The decision-making process, as Wong describes it, involved determining the importance of each decision and the power of each solution. Decisions were categorized as Tier 1, Tier 2, or Tier 3 (with Tier 1 indicating greatest impact). Solutions were categorized as Good, Better, or Best. “It was a big list,” Wong says. “There was going to have to be some tough decision-making.”

Another challenge was understanding the impact of each decision in relation to other decisions. Wong says the team relied heavily on the Scenarios tool for understanding decision impact. “We used Scenarios to help the architect think about cost items holistically and to focus on the right things.”

“UCSF Health was able to quickly understand and evaluate the options the team presented us. Join’s visual interface simplified this complex study and helped us arrive at the best decision for the project.”

UCSF Benioff Children’s Hospital Oakland, Sr. Project Manager, Design & Construction

Creating a living repository of project information

Decision-making on healthcare projects is inherently difficult, says Messinger. “Since projects can last multiple years, team members change, stakeholders change, design standards change, sustainability requirements change. Even on shorter projects, we need a way to make information visible for everyone; to document everything so we can go back and review our decisions,” he explains. “For design-builds in particular, it is the responsibility of the general contractor to protect its partners. Using a tool like Join allows us to memorialize those decisions and those sign-offs. We have the whole trail here of what was presented so that one year from now, or two years from now, if anyone has questions, we have all the answers, in one place.”

Because hospital projects can last as long as 10 years, it can eventually become very difficult to locate information quickly and efficiently. “You don’t want to wind through meeting minutes and go down some very intensive routes just to find an answer to a team member or an owner question,” Messinger says. “We’ve had this happen already on this project, and we’ve been able to go right back to Join and say, ‘Yeah, here’s the sketch, here’s the numbers we showed at the time, here’s the date the item was reviewed and signed off on.’ To be able to share that to refresh everyone has been really valuable.”

Additionally, he adds, “a lot of times our field teams don’t necessarily have the same individuals that were on during design to be able to go back to, or maybe they weren’t in a particular meeting and can go back to that one database they need to access to get a quick answer. Join makes locating information easy. It’s just saved time for everybody.”

“Using a tool like Join allows us to memorialize those decisions and those sign-offs. We have the whole trail of what was presented so that one year from now, or two years from now, if anyone has questions, we have all the answers, in one place.”

Sr. Design Build Manager, XL Construction

Impact: A win/win/win!

XL expands its mass timber portfolio and Experience

33-year-old XL Construction, named by ENR California as the 2020 Contractor of the Year, was one of the first Bay Area companies to build commercially with mass timber and has a thorough understanding of that project type’s requirements [see sidebar].

Milpitas-Calif.-based XL can now add the first mass timber project on a UCSF campus to its growing portfolio of mass timber projects.

UCSF gets the mass timber project it wanted, at the price it wanted, as well as an outstanding owner experience in the process

By pitching mass timber for this important project, and utilizing Join preconstruction software to help make that project a reality, XL delivered both an iconic project and an unmatched owner experience to the client.

“We were able to create a process that provided greater efficiency, transparency, predictability, and cost transparency,” says Wong. “In the OAC meetings, the team would go to the dashboard section of Join and show UCSF Health the Items (decisions) that needed to be made and what would be reviewed at the cost meeting and evaluate where we were at.”

“Join was the bridge between the designer brain, the contractor brain, and the owner brain,” says Pastori. “It was like the translator that spoke the three languages.”

What would this process have looked like without Join?

“It would just have been this crazy spreadsheet,” Wong says. “I’ve done that world before; the spreadsheets with a thousand tabs, each representing a different proposal. It would be pretty clunky. Then you would have to make sure everyone was doing things correctly, that the numbers were lining up. And then there would be the wait for my output. So the cadence of information and transparency is not there because you are bottle-necking the ability to show where the cost is trending.”

Mass timber experts

Mass timber as a construction type is having a moment. No one knows this better than XL Construction. With 12 mass timber projects either built or in preconstruction (as of Jan. 2025), XL understands exactly what’s required to deliver a successful mass timber project.

The firm’s depth of understanding of those requirements was recently made evident in a Building Design + Construction (BD+C) article authored by XL Co-Founder and Executive Vice President Dave Beck. In that January 2023 article, aptly titled “How to Set Up your Next Mass Timber Project for Success,” Beck talks about the growing interest in mass timber buildings: “From a building standpoint, mass timber rivals traditional steel and concrete building materials in durability, seismic performance, and fire resistance, while being lighter in weight and resulting in less costly foundations. Additionally, because mass timber components are machined to a high precision (+/- 1mm), the installation on site is rapid, less noisy, and utilizes a smaller installation team than alternative materials.”

Many early design decisions and considerations need to be reconciled in order to plan a mass timber project and ensure a cost-effective and efficient construction process. Some of those decisions require early and collaborative conversations about: Construction type, Fire-resistance ratings, Member sizes, Grids and spans, Exposed timber (where and how much), MEP layout (and how systems are routed through the structure), Acoustics, Façade strategy, Concealed spaces, Connections, Penetrations. XL relies on Join to help the team make these critical decisions as early in design as possible.

“Join was the bridge between the designer brain, the contractor brain, and the owner brain. It was like a translator that spoke all three languages.”

Principal, RMW Architecture & Interiors

The building’s end users will enjoy a work environment that fosters both productivity and joy

UCSF Benioff Children’s Hospital is among the best in the nation for all 11 specialties ranked by U.S. News & World Report and has some of the best doctors and staff in the country. Go to the hospital’s website, and you’ll see photos of window cleaners scrubbing the exterior of the building dressed as superheroes. Therapy dogs in patient beds. S.F. Ballet members in the hospital rooms, dancing. There’s nothing the hospital won’t do to make its little patients feel and heal better.

The provider is equally driven to make its administrative support staff feel appreciated and honored, and the new ASB structure is physical evidence of this commitment. Says Pastori: “This building is designed to be that area of refuge, that respite, for the people that are dedicating their lives and careers to helping the patients of the hospital.”

UCSF Health’s McDonnell agrees. “The XL/RMW team has overcome multiple challenges to help us realize our first mass timber project. However, the ultimate beneficiaries will be the building’s end users. We believe they’ll be thrilled with the look and feel of their new workplace.”