How to Reduce Material Costs and Waste with Historical Data

Last year, input prices climbed 21.2% YoY. Trucking costs were up 16.3%. Volatile material costs and the supply chain are an inescapable reality for construction companies — and for their clients.

To be successful, contractors should not only understand how material shortages and costs can impact their bottom line, but also where the company can mitigate these issues by using trustworthy historical data to reduce material costs and concerns associated with it, including poor client trust and material waste.

The Hidden Traps of Material Shortages

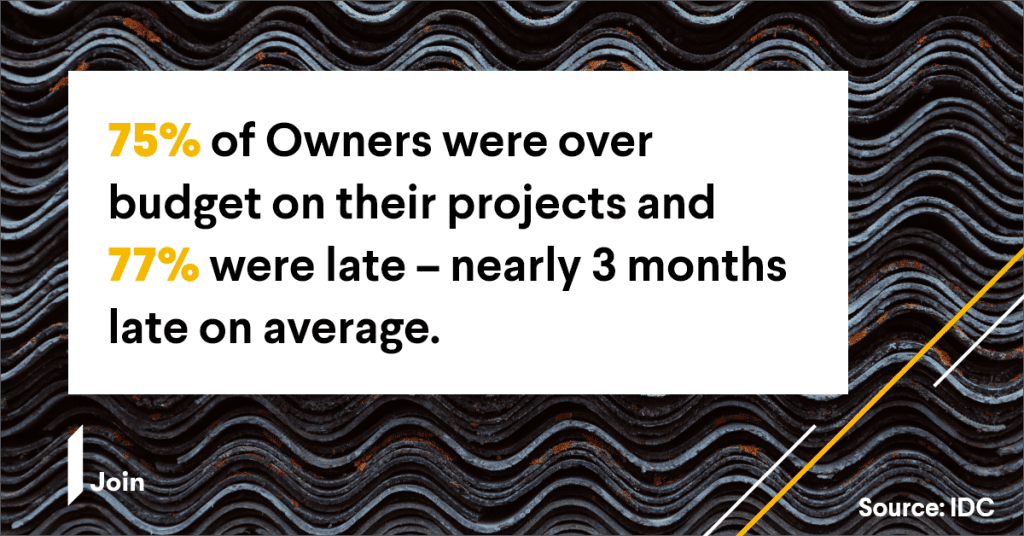

At face value, it is obvious that the volatility of material costs is hard on the construction industry. Uncertainty around prices and the supply chain can create delays and escalate project expenses, which not only reaps havok on the project budget, but can also frustrate Owners – or worse – lose their trust entirely.

In a recent survey, they found 75% of Owners were over budget on their projects, and 77% were late – nearly 3 months late on average.

An even greater issue, however, is the way contractors react to those material shortages. If they make decisions without trustworthy data, the negative impact of material costs can skyrocket. Best case scenario, they’re not reacting at all, they’re being proactive with the historical data they have.

Let’s take a look at some missteps businesses can avoid to increase cost certainty and maintain relationships with Owners.

Buying Late

In today’s built environment, the timing for ordering materials is very different from when materials would have needed to be ordered ten or even five years ago. Today, if a contractor orders building materials based on when it’s “always been done,” then they are starting that project behind schedule. With today’s supply chain issues, the likelihood of being hit with delays is extremely high. In some cases, it may be possible to pay extra to speed up delivery, but that will be a hit to the project’s bottom line.

Additionally, a delay in materials means the portion of the build reliant on said materials cannot continue — affecting all subsequent steps in the project. The expenses tied to this delay in the build, the impact on labor, and subsequent uninformed decisions which are made to counteract this can simply pile on the financial losses.

Buying the Wrong Amount

Many contractors rely on bulk purchases as a workaround for material delays and fluctuating costs. This can lead to excess material. Even if the material can be used on a later project, the company is now faced with storage of the material, which is an unnecessary and unplanned cost.

Some contractors simply buy early when fluctuating costs are lower, but do not buy in bulk. While this lowers the risk of buying in excess, it can mean that there is not enough material to complete the project, unless they are purchasing based on historical data that allows accurate material forecasting.

Planning a Project Poorly

Project profitability begins in the bid stage. If estimators are working off data that does not empower them to consider fluctuating material costs, then that item will be planned for poorly. Overestimate and your company can lose the bid; underestimate and your team is set up for a loss in profit before a project has even begun.

With accurate data, however, the project scope and cost will be more accurate — making the project more profitable. With a good tool for storing and pivoting your historical data, you can more accurately compare projects and use that data to more easily spot project risks – increasing Owner confidence.

Leverage Data to Plan Better for Material Shortages

As a web-based decision tracking software, Join ensures anyone can record project decisions, costs, delays, and budget changes in real time. Likewise, those key data points can be accessed at any time, from anywhere. By automating the data and empowering stakeholders to utilize it, contractors are able to better plan for shortages.

With the launch of Join Forecasting, contractors can leverage their historical data to make accurate project comparisons and conceptual estimates in minutes instead of days.

Calculate and predict cost escalations

By ensuring data integrity, contractors maintain an accurate record of costs and budget changes from project to project. This historical data from similar projects allows an accurate projection of price escalation as it might impact current projects. Managers operating with trustworthy data can then order accurately in advance — while costs are lower. Additionally, by analyzing the decision history of past projects, stakeholders may be able to identify ways to reduce costs to account for price escalations.

Make decisions faster

The transparency and accuracy of data does not simply make it easier for contractors to make decisions on future projects; it also ensures those decisions are made faster.

According to a 2020 FMI Industry report, construction professionals spent over 14 hours per week on tasks like looking for project information and dealing with rework.

With the right tool, there’s no searching for the data, or questioning the validity of a spreadsheet algorithm. With visible and trustworthy data, decision-makers can confidently make fast decisions and take advantage of low material costs.

Mitigate Risk Now and in the Future with Data

Construction companies are not the only people impacted by a volatile material market. Clients also bear that brunt — and they feel it worse when they are kept in the dark about the current realities around material costs. By using historical data to project scope and cost decisions during pre-construction, companies can lower their risk, while strengthening their relationship with clients.

Better planning, for higher cost predictability

With the fluctuation in material prices even before the pandemic, it is common to build material cost contingencies into the project scope. However, without strong historical data, these contingencies can be wildly inaccurate.

In contrast, contractors who utilize decision-tracking platforms like Join are able to make more accurate project comparisons and forecast how material costs will escalate through the scope of a project. This ensures contingencies within the project scope are made thoughtfully in order to not simply protect against loss, but actually generate a higher profit.

Be more transparent

By leveraging historical data, contractors are able to not only accurately predict how material costs may change, but they can walk clients through data-backed rationale that explains contingencies within the project scope. That means the relationship with the client begins with full transparency, which leads to better trust overall and, ultimately, repeat business.

Want your project comparisons and conceptual estimates to be backed by accurate historical data? Book time with our team >