Target Value Design for Beginners

The construction industry is going through a type of evolution. New technologies have rapidly advanced that evolution but also have outpaced the doctrine that guides the industry. The industry needs to take more modern delivery methods and understand them conceptually to find innovative ways to apply them. Target Value Design falls into this category.

What is Target Value Design?

Target Value Design (TVD) is “a management practice that drives the design and construction to deliver customer values within project constraints”. Whenever I am breaking down a new concept, it helps me break it into two distinct categories. The first is the doctrine or philosophy associated with the idea, and the second is the actual implementation practices around it.

The definition of TVD does a great job in articulating the doctrine or philosophy behind the concept. The goal of TVD is to continually monitor and deliver on the project owner’s target value. The most common goal is a particular cost constraint or budget, but that is not the only goal that can drive a TVD project. Schedule, carbon footprint, ROI for the facility and spaces within the facility, and the spatial experience can all be part of a project’s target value.

The other TVD philosophy component moves from a specific point in time approach found in Design-Bid-Build projects and moves to a continuous measurement and improvement model throughout the project life cycle. These changes to the delivery method allow contractors and owners to become more agile in approaching the inevitable variables that all projects encounter.

Now that TVD is defined, we can look at its current implementations.

Case Study: How DPR successfully navigated TVD for a new hospital project with Atrium Health.

Lean Construction Delivery

TVD has been synonymous with Integrated Project Delivery (IPD). IPD is a construction project delivery method that seeks to align all stakeholders to a single shared goal of delivering a project.

IPD has seen great success but limited application due to the contractual obligations, team structure required to succeed, and in construction years, it is a relatively new concept.

There is a trend of other more established project delivery methods adopting some of the Lean principles from IPD. Specifically, Design-Build has seen an increase in the use of TVD to manage projects to help maintain clarity on the project goals.

Design-Build is a construction project delivery method that creates a single contract between the owner and the design-build team, from initial concept through delivery. There are contractual differences between IPD and Design-build that have made Design-Build a preferred method for many owners and contractors.

Target Value Design Workflow

TVD starts from the initial conceptual designs through to the final CO for the project. The continuous nature of TVD is a critical distinction from value engineering, which is a reactive process to significant overruns of cost, schedule, or scope. TVD, on the other hand, is a continuous process that applies the budget in the right places..

The TVD project teams will meet regularly throughout the project, usually every two to three weeks. The TVD methodology requires more time and ongoing involvement from estimating resources to track the budget.

Estimators’ participation is a shift in labor, which many perceive as a waste of resources. However, the skyrocketing cost overruns on construction projects outweigh the cost of continual estimation and tracking during construction. The resulting savings and cost transparency ultimately deliver a superior experience and finished product.

The project team continually analyzes the budget and options to provide regular feedback on the project progress. The team is empowered to offer solutions that maintain the project’s quality and goals while still delivering the desired value.

When a team is value engineering, they are usually looking to drop project scope, “Oh, we are over budget; this building doesn’t need an atrium. Perfect, we are back on budget.” On a project utilizing TVD, “if we see more cost than anticipated in the common spaces, we could think there is a more cost-efficient option for the foundations that could hold to the budget, but we might need to look at the benefits of the atrium, Porte-cochere, and green space areas of the project to protect the scope and value of the project for our customer.”

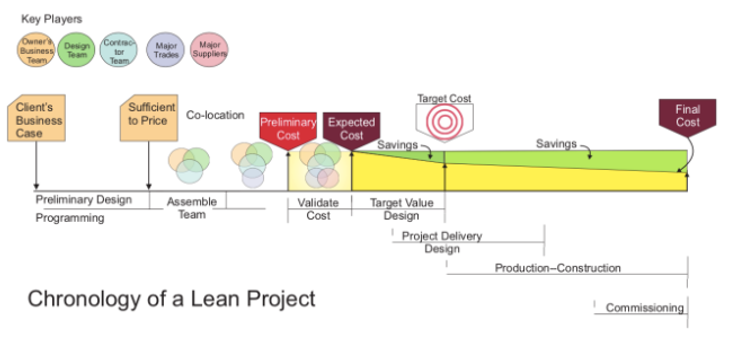

Below is an example chronology of a TVD project. A critical aspect of the project delivery team is they are assembled early in the design phase. The team’s first priority is to validate the project’s business case and collaboratively work on the TVD process from the design phase until close-out.

Source: Chronology of a Lean Project (Courtesy of Dick Bayer, The ReAlignment Group Canada, Ltd, and leanconstructionblog.com)

Construction Industry Impact

The implications of effectively implementing and executing Target Value Design cannot be understated. Implementing this new methodology allows construction teams to move towards advanced means and methods while delivering superior value to their customers.

This process transforms the project teams’ experience while providing reliable cost, schedule transparency, and reduced risk. The key ingredients to achieving this “Holy Grail” for construction are the people (project team), the process (TVD), and the technology.

Read about how DPR successfully navigated TVD for a new hospital project with Atrium Health.